Among the injection moulding variants offered by SPM are innovative, highly technical solutions such as multicolour and multiple material processing.

The SPM presses cover a complete range, for all sizes, to support multiple material & multicolour injection moulding with 2 or also 3 materials at the same time.

In the market, the automotive field was one of the first to use these techniques. Thereafter, these moulding processes extended to many other production fields, such as electronics, telephones, sports articles, etc.

The technological development path for these processes is under continuous development and this market is forecast to grow significantly.

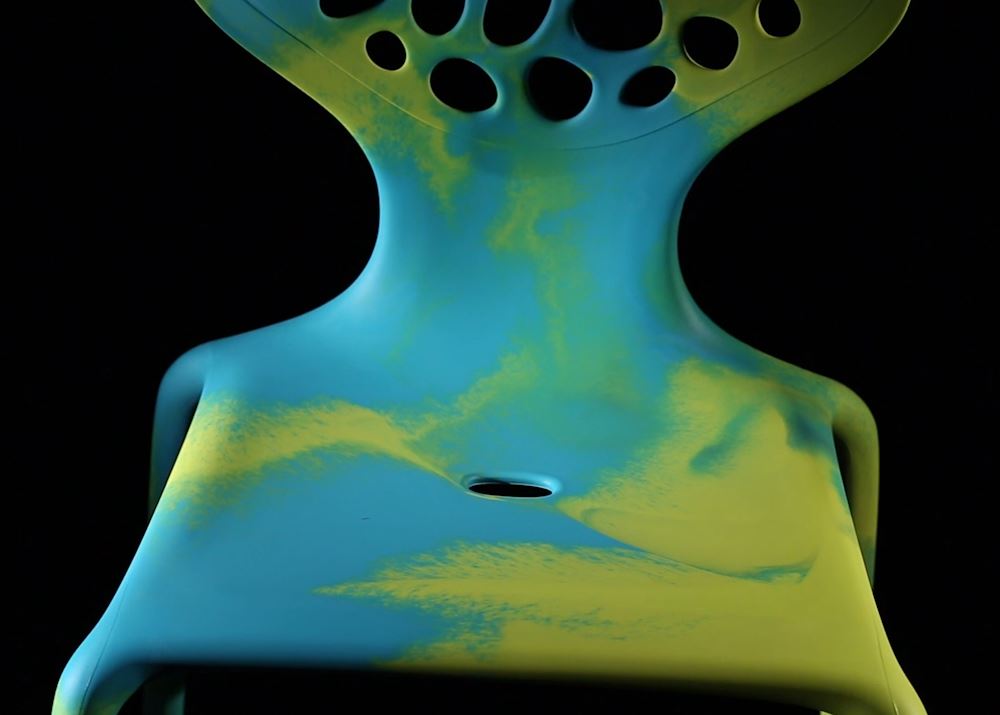

Multiple materials or multiple components

The multiple material or multiple component process was developed to satisfy a market that tends to require items with highly specific physical/structural characteristics. The requirements are the most disparate, from those technical-functional, to those purely aesthetic design. For this reason “stiff” materials are combined with “soft” materials, or aesthetic materials but less structural, joint with other materials exactly to the opposite,

namely with high mechanical performance but less aesthetic.

Multiple colours

The multiple colour process results in appearance quality and characteristics that would otherwise require high production costs. Moulding always guarantees excellent quality at a low cost. In some cases, multiple colour moulding has replaced traditional processes such as painting or screen printing. SPM multiple colour moulding offers a better quality appearance and lower components cost, rather than moulding of separate components followed by assembly phase. In other cases impossible goals are achieved with other types of technologies.

SPM has increased his experience in this technology and today it’s very happy to share, for new projects to meet the needs of customers.