The activities of inspection and testing of the moulds built by SPM have become strategic for the company’s core business. It is not just a question of quality, operation and efficiency of the mould; rather, to fully grow the exclusive ability to add value to the services offered by SPM.

The interdisciplinary structure within SPM guarantees those high-level requirements of efficiency and precision that only a few competitors on the market can offer.

The most important details that describe the service of pre-production testing are the following:

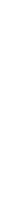

- Availability of any tonnage, from 40 to 6,000 tonnes(Largest injection press in the world)

- All moulding technologies: traditional injection moulding – multiple materials 2/3 even using high tonnages (greater than 2,000 tonnes) – air moulding.

- Exclusive and patented moulding technologies: BIM® – SIM® – FIM® – EXTIMO® – PIM®

- Certified metrology testing (recognized by our main multinational customers) with release of statistics (CP – CPK)