For SPM attaining each result means fully meeting market needs. This is true for all market segments. Services, products, operating process, research and development are all aspects integrated in the quality system shared according to the standard UNI EN ISO 9001:2015.

SPM was among the first companies in the field to adopt a quality system: our first certification dates back to 1 June 1998. For SPM, application of quality procedures means creating an organization within the company capable not only of meeting the requirements of the UNI EN ISO 9001:2015 standard but also of assimilating innovation and flexibility without influencing production time and costs.

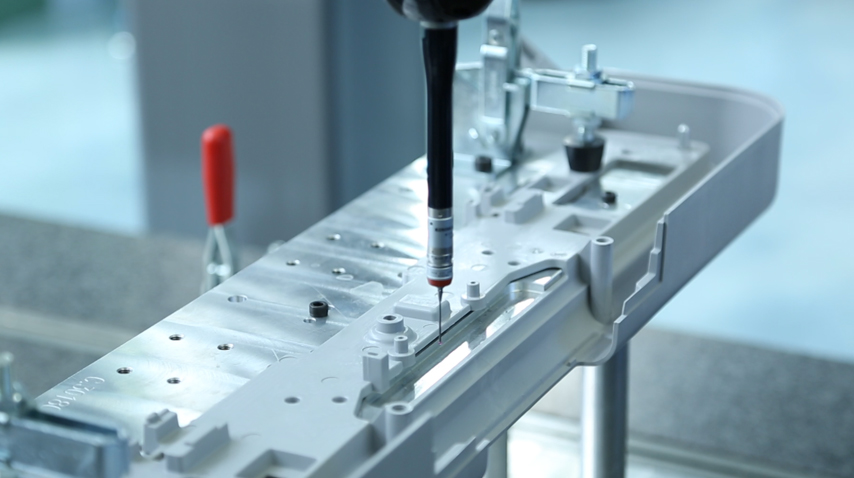

The SPM quality system is strictly applied to all company processes, not only in production and engineering but above all in areas like quality control, sales, and purchasing, all essential parts of retaining customer loyalty. For some time SPM has gone beyond the classic documentation used in quality systems (procedure sheets, instruction manuals, etc.) using new, more effective tools for information and sharing an internal digital network that involves all of the operators in all departments, keeping them up to date with all data that accompanies orders and other activities. Frequent audits by certifying bodies guarantee maintenance of the high quality standards in SPM and allow the comparison required to strive for, maintain, and exceed the improvement objectives.

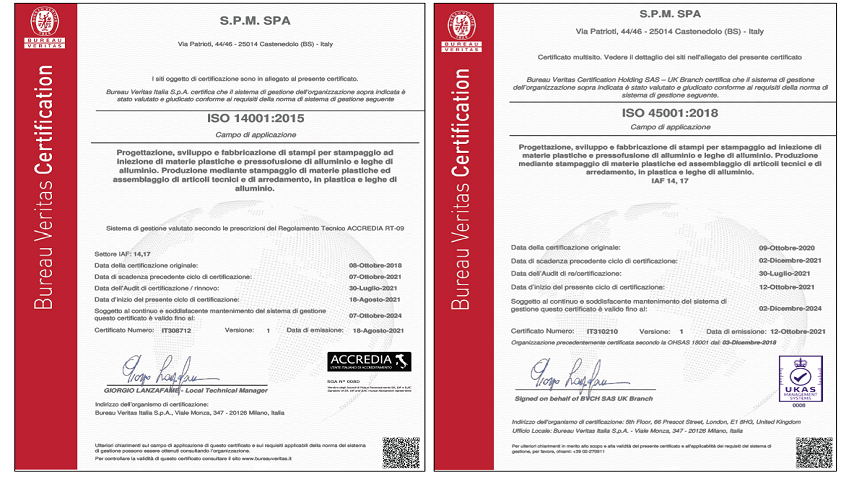

SPM obtained ISO 14001 environmental certification and OHSAS 18001 certification for occupational health and safety, supporting and demonstrating the great respect for the environment and the health of its employees that have always been part of SPM’s corporate philosophy.